How Mechanical Design Will Always Be Relevant

With the modern age becoming increasingly digital, one of the questions we at RF3 Design Ltd is whether the mechanical design work we do is getting less in demand. This isn’t at all the case, for a couple of very important reasons. Today we’re taking a few minutes to tell you why good old fashioned hardware will never die out:

Mechanical Design: Analogue Machinery in the Digital Age

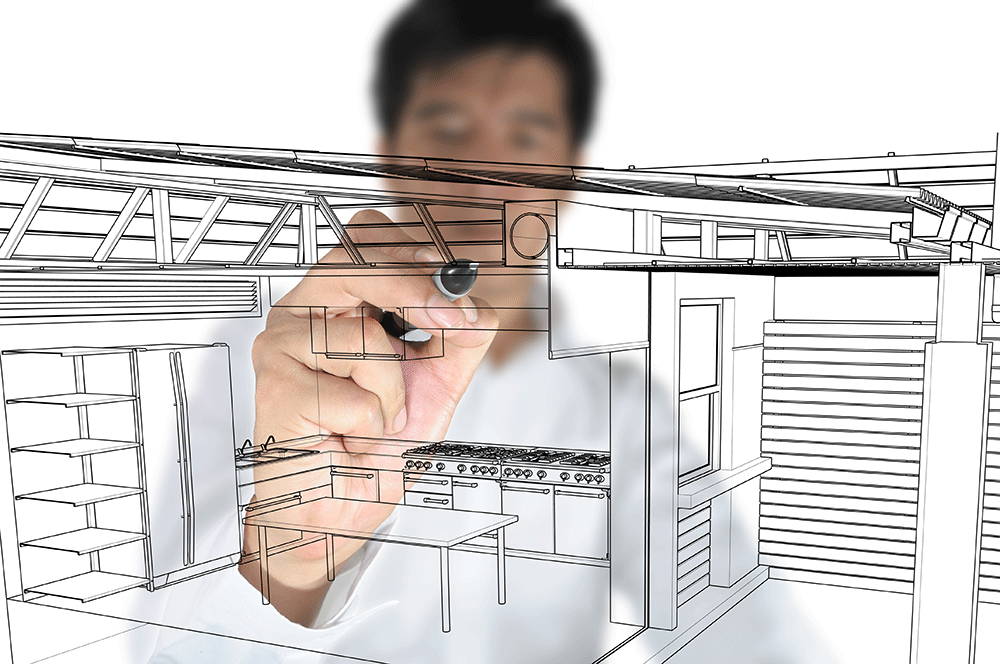

It’s likely that you’re working much more with digital equipment these days, but the fact remains that without good old fashioned mechanical design, our lives would be vastly different – and much more inconvenient – than they are.

It’s likely that you’re working much more with digital equipment these days, but the fact remains that without good old fashioned mechanical design, our lives would be vastly different – and much more inconvenient – than they are.

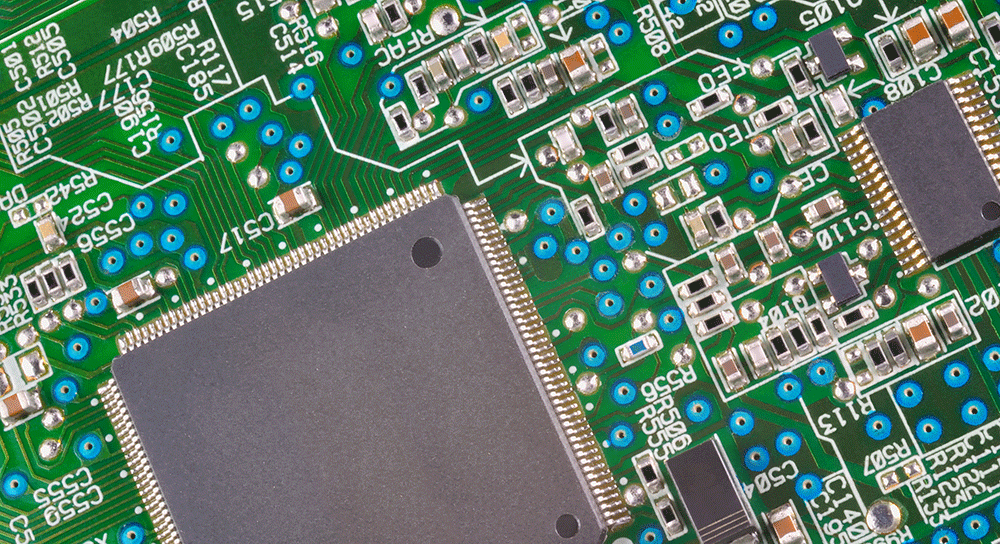

It’s worth remembering that without their mechanical parts, your digital tech wouldn’t exist. Everything from the processor that works as the brain for every piece of electronic equipment to the accelerometer that tells your phone whether it’s being held portrait or landscape is a part of mechanical design. Almost every single industry sector there is has essential machinery in a full analogue state – from the handyman’s drill to the life-saving diagnostic equipment in your local hospital.

There are also many places in which digital tech can be cheaper, quicker and easy to use – but still doesn’t perform as well or just doesn’t feel right. There are many professional photographers, even those young enough to have always lived in a world where digital photography has always been the industry standard, who continue to use film because somehow it just looks better. As we posted last month, many music production studios use equipment which should, by now, be archaic, because it simply creates sounds more appealing to the human ear that digital counterparts can.

Also, don’t forget that every piece of digital technology – the laptop or desktop computer that you keep in the office, the tablet you have to keep you informed when you’re on the road, and the phone you use when your children have “borrowed” your tablet to watch Spongebob or Dexter, were all created on a production line by mechanical robots.

We need it.

A new electrical product can have everything going for it – strong marketing, little direct competition, and a good visibility campaign, but if its electronic design isn’t absolutely perfect, then the product could be victim to faults, unnecessarily expensive components, or heat and power problems which can cause a product to fail.

A new electrical product can have everything going for it – strong marketing, little direct competition, and a good visibility campaign, but if its electronic design isn’t absolutely perfect, then the product could be victim to faults, unnecessarily expensive components, or heat and power problems which can cause a product to fail.

The design process involves turning a simple idea, based on the needs of consumers, into a complete product that meets these needs. The

The design process involves turning a simple idea, based on the needs of consumers, into a complete product that meets these needs. The